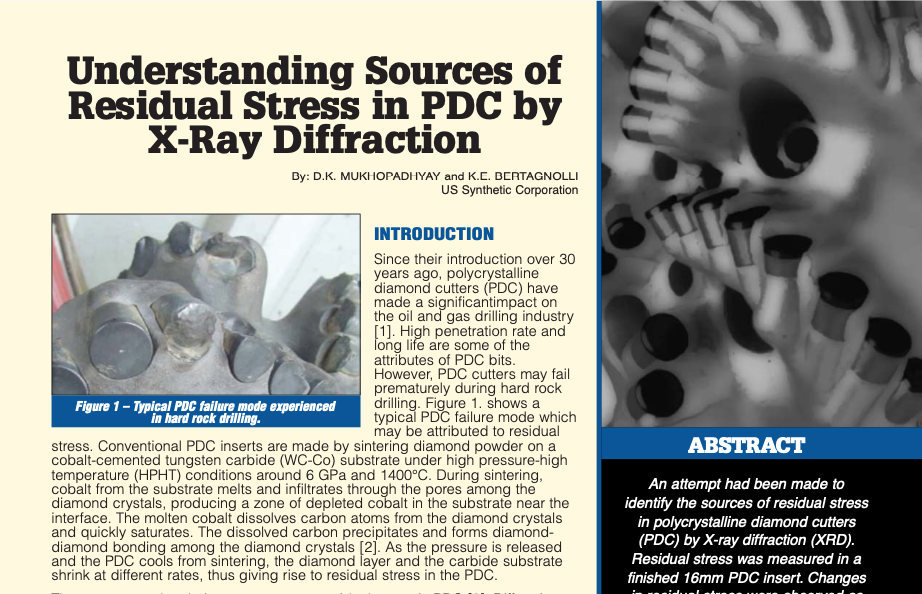

With more than 40 years of diamond-engineering experience, US Synthetic has worked hard to deliver advanced Polycrystalline Diamond (PCD) material for durable 3D Printer Nozzles. Our diamond sintering process requires extreme heat and pressure. Typically, diamond is sintered at a temperature of around 1400°C (2550°F).

Maintaining extremely high pressure during the sintering process allows the diamond to remain in its natural form. This typically requires pressures of around 60 kbar (nearly 1,000,000 psi). To achieve these extremely high temperatures and pressures simultaneously, US Synthetic uses proprietary cubic press technology. As soon as the press reaches the desired pressure, electric current flows through a resistance heater embedded in the pressure cell to generate the required high temperatures. These conditions are maintained long enough to ensure complete diamond-to-diamond bonding of the individual crystals.